Weld line issue is a common surface defect of plastic products. It is not just an aesthetic issue but can also affect the structural properties. Other than part design, gate location design is another major factor of weld lines. Take automotive products as an example; they are large thin-shell parts with large L/t ratio, and the gate design mainly dictates the resulting product quality. To simulate the molding process of this automotive part, users traditionally have to set the gate locations based on their experience at the pre-processing stage, and then run filling analysis. The calculation time can be more than 3 hours because the mesh element amount is considerably large for big parts. When the analysis is done, users have to check if the weld line positions are acceptable. If not, they have to repeat the process as mentioned, which can be very exhausting and time-wasting. In today’s fast paced industries, the time spent in the product design stages is getting more and more important. A robust and upgraded CAE simulation tool is required.

To meet these demands, Moldex3D has made many breakthroughs in the latest version, R16. First, the L/t workflow has been improved in the pre-processing tool, Moldex3D Designer. Moldex3D R16 also offers user-friendly interface, enabling users to quickly evaluate different gate designs on L/t results, and then output the mesh. Second, Moldex3D R16 Quick Flow analysis can perform high speed filling analysis for users to view the weld line results. Combining the new L/t workflow in Designer and Quick Flow analysis mentioned above can greatly enhance the efficiency of gate position designs.

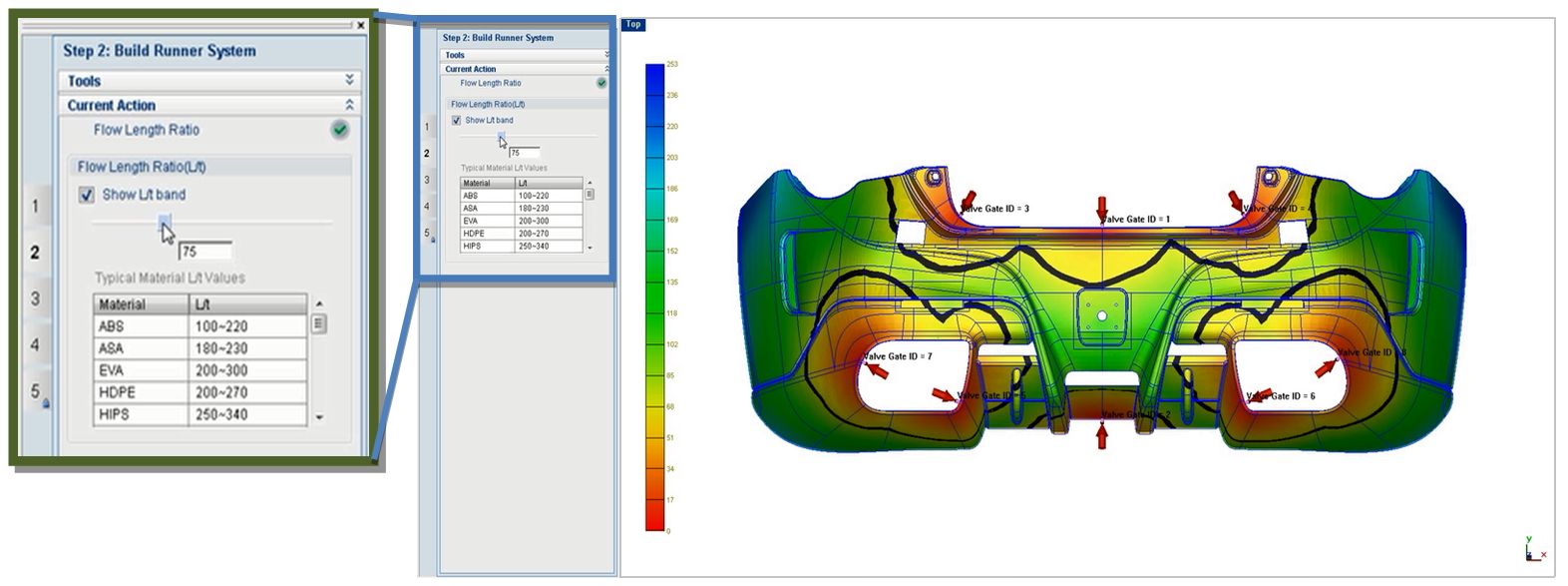

The following figure is a case of an automotive front panel. Users can observe specific L/t value areas in Moldex3D R16, which provides appropriate L/t ranges of different polymer types so that users can decide proper gate designs.

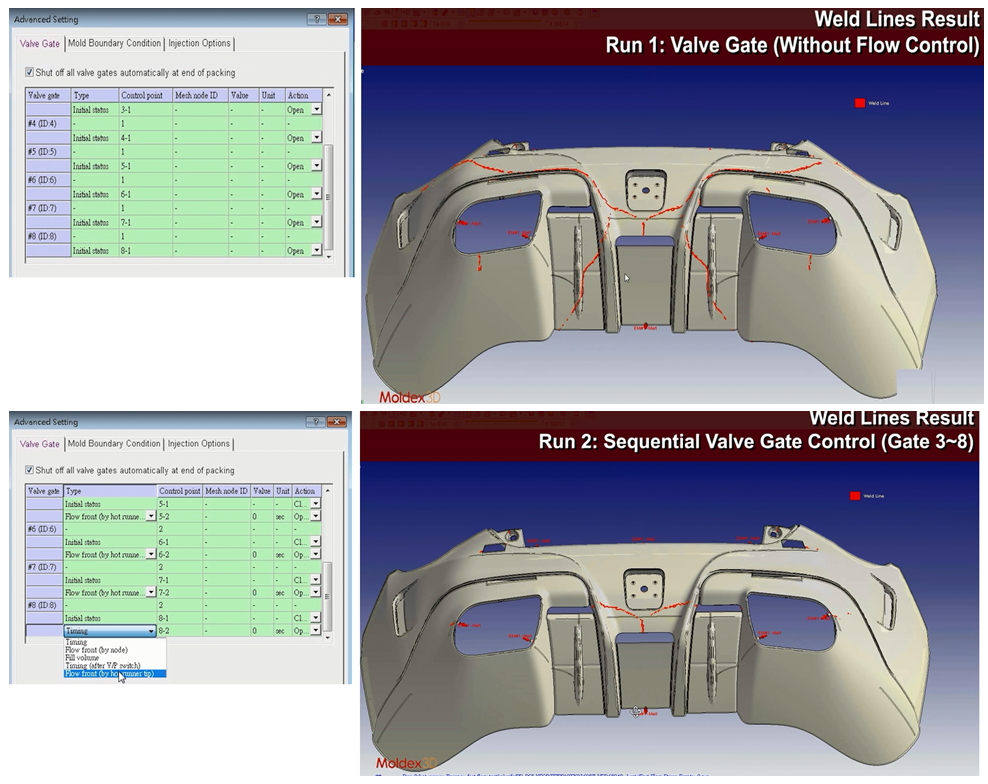

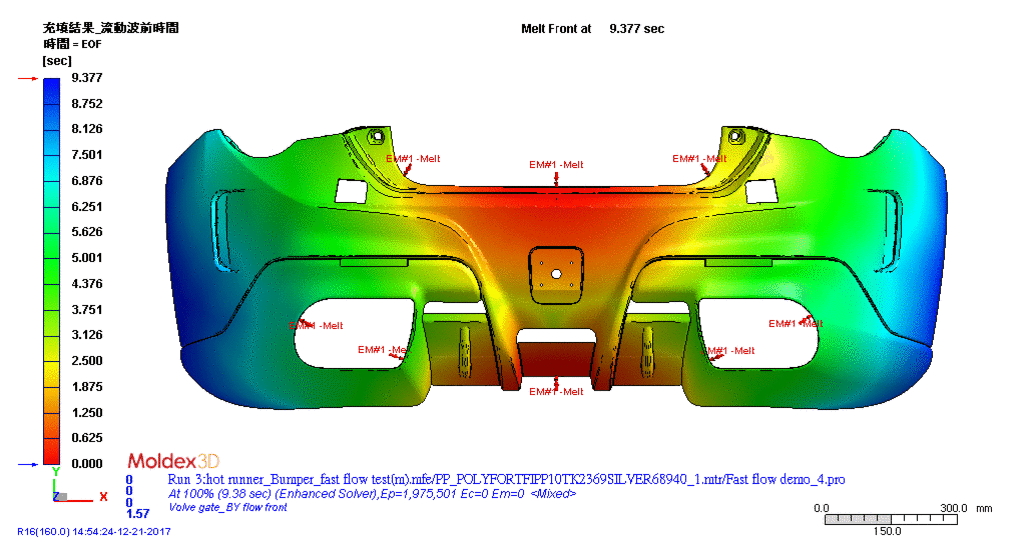

As shown in the figure below, Quick Flow Analysis is able to validate the effects of different gate designs toward weld lines in a short time. Under the fixed gate criteria, Quick Flow Analysis can also simulate how different valve settings affect the weld lines.

Crucial time calculation of is compared below. Among the two flow analysis options, Regular Flow analysis costs 2.6 hours, while Quick Flow analysis only costs 10 minutes with 95% calculation time reduced.

| Â | Elapse CPU Time |

| Regular Flow | 9397 sec (2.6 hr) |

| Quick Flow | 574 sec |

Â

Therefore, we can see that the new L/t workflow of Designer and the Quick Flow analysis in Moldex3D R16 can both significantly benefit plastic components with a large surface by providing efficient simulation solutions to shorten gating iteration time from hours to minutes.

Alcohol Pad Packaging Machine,Alcohol Pad Packaging Machine for Medical Use,Medical Alcohol Tablet Making Machine

Changzhou shanglai automation equipment co., ltd , https://www.slautomate.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)