Polyurethane (PU) foams are used for a wide range of applications in today’s manufacturing world. PU foam has porous, low-density and high-strength properties. In addition, by adjusting the proportions of the ingredients, we can attain rigid polyurethane foam and flexible polyurethane foam with different porosities. In the polyurethane foam manufacturing process, in order to determine the foam location within the part and predict the dynamic behaviors of the molding process, CAE simulation tools are commonly used for product design and optimization. Moldex3D PU Chemical Foaming Molding (CFM) module covers polyurethane foaming simulation and foaming kinetics simulation, enabling users to comprehensively understand the dynamic behaviors in the filling and foaming stage of the polyurethane foaming process.

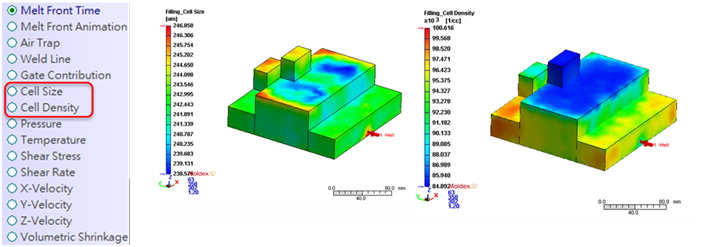

In particular, due to the low viscosity of PU material, mold rotation technique is often employed to enable better foam material distribution in the filling and foaming stage. This will help to obtain more uniform PU foam properties, thus improving the overall qualities of PU foam molded products. Other key factors for evaluating the mechanical property of PU foam material are cell size and cell density. With Moldex3D simulation, users can easily visualize and understand the effect of mold rotation and cell information in different areas of the part to gain a better understanding of microstructure and further control the product quality before production (Fig. 1).

Fig. 1 Calculating the cell size and cell density distribution can help user to have the ideas of microstructure

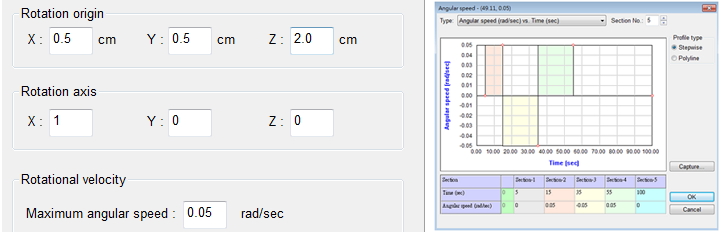

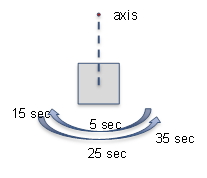

Through Moldex3D simulation, users can gain valuable information on the flow and foaming behaviors considering the influences of gravity and centrifugal force during the mold rotation. Important process parameters such as rotation cycle and angular velocity (Fig. 2) are considered during the mold rotation calculation (Fig. 3). Users can visualize the molding process through animations.

Fig. 2 Mold rotation process parameter setting: rotation cycle and angular velocity

Fig. 3 Illustration of 30-degree mold rotation

In summary, with Moldex3D PU Chemical Molding analysis, users can fully understand the effect of mold rotation on the filling and foaming behaviors of PU foams. More importantly, users can understand the microstructure which is essential for predicting the mechanical behavior in FEA software. The valuable information is very essential for users to better predict and evaluate the PU foaming process to ensure better product quality.

Vented Twin Screw Barrel,Vented Twin Parallel Bimetallic Screw Barrels,Twin Parallel Bimetallic Screw Barrel

Zhoushan Dinghai Jinxing Plastic Machinery Factory , https://www.jinxingscrew.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)