Product Description

Material:Â PP material or fiberglass material

Specifications:Â produce according to customer requirements

1.Product Mix:Â HEPA+activated carbon honeycomb+initial efficiency filter cotton

2.Product Desription:HEPA(High Efficiency Particulate Air) for the dus which is more than 0.3 micron, the filtration efficiency can be as high as 99.97%, is a good air purification product. HEPA can be divided into three materials: PP filter paper, glass fiber and composite PP+PET filter paper, and it can be made into a variety of shapes according to customer requirments.

Features:Â Low wind resistances, high dust holding capacity, high filtration precision, and it can be processed into various sizes and shapes acccording to customer needs, and suitable for different models.

Usage:Â HEPA is windely used in air purifiers, central air conditioning, clean plant and other fields, and it is used to dust and pollen;

Combine the HEPA and active carbon honeycomb together, it not only has the filter function to remove dust and pollen filter, but also has the function of removal of formaldehyde, ammonia, oluene, trimehylamine and smell of cigarettes and other harmfull gases.

Combine the HEPA and Nano silver sponge primary efficiency mesh together, it cannot only remove the dust and pollen filter, but also can inhibit and kinn Staphylococcus aureus, E.coli and other harmful bacteria.

3.Performance Indicators

| The Name of the filter paper | Filtration Efficiency(%) | Wind Resistance(5.33cm/s) | Service Life |

| Glass Fiber | >99.97 | >410Pa | 8-12 Months |

| PP Fiber | >99.9 | 70-90Pa | 8-12 Months |

| PP+PET Composite | >99.9 | 40-65Pa | 8-12 Months |

Curve: The trend of wind speed and filtration efficiency: 5.33cm/s(0.32L/cm2.min)

Product Image

FAQ

Why choose us? What are the advantages of us?               Â

1 We have been engaged in the export of air filters for more than 12 years.

2 We can provide OEM and ODM services, sample production and services according to your requirements.

3 18hours of online customer service, you can get prompt and quick online reply.

4 We have specialized factory and brand.

5 The dimension can be customized.

6 The delivery date will be within 2Â weeks.

7 With With high-tech RÂ & DÂ team and design capablities.

8 equipped with professional service staff and skilled technical staff.

We sincerely hope that our relationship can go further, we believe that our professional products can bring you a better future, we look forward to working with you for your cooperation. And invite friends from all over the world to work together.

Welcome to your inquiry. Your satisfaction is our pursuit!

Inquiry method

Â

Â

Â

Â

Â

Â

Â

Â

Glass Fiber H13 HEPA Air PurifierÂ

Product Description

Material:Â PP material or fiberglass material

Specifications:Â produce according to customer requirements

1.Product Mix:Â HEPA+activated carbon honeycomb+initial efficiency filter cotton

2.Product Desription:HEPA(High Efficiency Particulate Air) for the dus which is more than 0.3 micron, the filtration efficiency can be as high as 99.97%, is a good air purification product. HEPA can be divided into three materials: PP filter paper, glass fiber and composite PP+PET filter paper, and it can be made into a variety of shapes according to customer requirments.

Features:Â Low wind resistances, high dust holding capacity, high filtration precision, and it can be processed into various sizes and shapes acccording to customer needs, and suitable for different models.

Usage:Â HEPA is windely used in air purifiers, central air conditioning, clean plant and other fields, and it is used to dust and pollen;

Combine the HEPA and active carbon honeycomb together, it not only has the filter function to remove dust and pollen filter, but also has the function of removal of formaldehyde, ammonia, oluene, trimehylamine and smell of cigarettes and other harmfull gases.

Combine the HEPA and Nano silver sponge primary efficiency mesh together, it cannot only remove the dust and pollen filter, but also can inhibit and kinn Staphylococcus aureus, E.coli and other harmful bacteria.

3.Performance Indicators

| The Name of the filter paper | Filtration Efficiency(%) | Wind Resistance(5.33cm/s) | Service Life |

| Glass Fiber | >99.97 | >410Pa | 8-12 Months |

| PP Fiber | >99.9 | 70-90Pa | 8-12 Months |

| PP+PET Composite | >99.9 | 40-65Pa | 8-12 Months |

Curve: The trend of wind speed and filtration efficiency: 5.33cm/s(0.32L/cm2.min)

Product Image

FAQ

Why choose us? What are the advantages of us?               Â

1 We have been engaged in the export of air filters for more than 12 years.

2 We can provide OEM and ODM services, sample production and services according to your requirements.

3 18hours of online customer service, you can get prompt and quick online reply.

4 We have specialized factory and brand.

5 The dimension can be customized.

6 The delivery date will be within 2Â weeks.

7 With With high-tech RÂ & DÂ team and design capablities.

8 equipped with professional service staff and skilled technical staff.

We sincerely hope that our relationship can go further, we believe that our professional products can bring you a better future, we look forward to working with you for your cooperation. And invite friends from all over the world to work together.

Welcome to your inquiry. Your satisfaction is our pursuit!

Inquiry method

Â

Â

Â

Â

Â

Â

Â

Â

Â

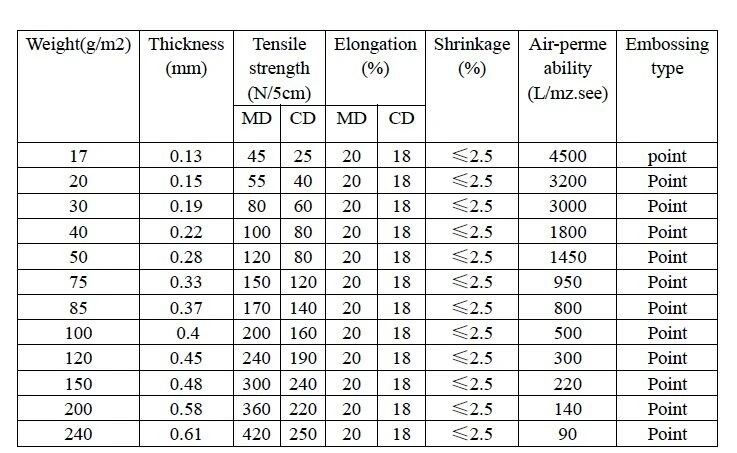

Non Woven Fabric

FY-hengfa nonwoven Fabric series: PET Polyester Spunbond Non woven, Meltblown Nonwoven, Activated Carbon Nonwoven Fabric, Nonwoven Filter Bag,Nonwoven Fabric For Auto Filter.

Such as:

100% PET/PP spunbond nonwoven fabric.

It is similar to filament yarn production. From the chips storage, the polymer is vacuum-fed to a dosing station on top of the extruder. Inside the extruder, it becomes melted and homogenized. Passing a filter system and a spin pump, the melt is fed into the spin beam or spinnerets, which form a curtain of filaments. The filaments are cooled by means of a stream of air in a blowing area, drawn by aerodynamic forces and then transported to the downstream discharge channel. For nonwovens, instead of a further stretching process for filament yarns, the filaments are swirled around and then deposited on the wire mesh belt as a random nonwoven. This web is transferred to a bonding calender that uses heat and pressure to set such physical properties as tensile strength and elongation of the final product. After cooling, the material can be wound.

Product :Spun-bonded Nonwoven

Material :100% polyester

Width :0.15-3.20m.

Specification:1000M-4500M/roll or customized

Weight :10gsm-260gsm

Use :

1. Medical : face mask ,surgical cloth ,bedsheet ,disposable cap , shoose cover .

2. Packing : shopping bag , tablecloth ,wallpaper ,compund packing material .

3. home textile : pillow case ,mattress cover ,linling .

4. Industry : protect the crop from insect .cold weather .filtration materials

Non Woven Fabric,Pet Non Woven Fabric,Activated Carbon Nonwoven Fabric

Hebei Fangyu Trade Co., Ltd. , https://www.laderytrading.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)