Ms. Li Lixin, application expert of Shell passenger vehicle oil products, as a special guest, was presented at the GRC 4th 2012 Transmission Technology Symposium hosted by Jifu Power Technology (China) Co., Ltd. in Wujiang, Jiangsu Province recently. “The trend of changes in the viscosity of transmission oils†was discussed in detail on how to achieve high-efficiency, low-carbon transmission solutions for lubricants and the participants.

The role of lubricating oil is extremely important for gearboxes that are an important part of automotive powertrains. For both traditional MT/AMT, AT and new technology CVT, DCT, and Shell have corresponding transmission lubricant solutions. Transmission lubricants that have undergone stringent global bench tests and long-cycle road tests have been certified and used by most major OEMs.

In recent years, reducing CO2 emissions and improving fuel economy have been the main goals of transmission development. The development of various new transmission technologies poses very stringent challenges to lubricants. For example, various new friction materials for DCT and AT require that the cooperation of oil and friction materials can provide more efficient transmission and smoothness. Shifting and stable friction characteristics; AT requires lubricants to have lower viscosity (lower viscosity, less energy loss), effective lubrication of gears with a wider range of speeds, and leading transmission manufacturers require Provide life-long maintenance-free; DCT technology requires a lubricant to meet the needs of manual gearbox and automatic transmission. In addition, in Europe, the United States, Japan, and other Asian markets, transmission lubricants are subject to traditional regulations, such as Dexron, Mercon, and the new OEM specifications, how to develop a single oil product to meet as many technical specifications as possible and OEM requirements simplify the selection, reduce transmission oil inventory, reduce risks, and pose very difficult challenges to oil suppliers.

Ms. Tong is primarily responsible for Shell China automotive OEM and automotive component technology project support, and has a very rich technical background and experience in lubricants. She spoke at the meeting: In terms of environmental protection and fuel economy, Shell was proposed as early as in 2002. The concept of "Driveline Lubricant": With the use of Shell's engine oil technology, the new Shell Spirax range of transmission oils delivers more efficient transmission efficiency and fuel economy.

Shell has closely cooperated with the world's leading manufacturers of transmissions and transmission components in the automotive components industry, and has cooperated with many automotive OEMs to develop experience and provide the most suitable lubrication technology solutions. At the same time, Shell China is also actively and leading domestically. Manufacturer cooperation. Shell also has a very strong global R & D capabilities, with R & D centers in Germany, the United Kingdom, the United States and Japan. In order to better support the development of China's business, in August 2011, Shell's first lubricant service center in China was also operational in Zhuhai City, Guangdong Province. Chinese customers will then have the opportunity to experience Shell's lubricant technology capabilities. The center is part of Shell's downstream growth strategy, enabling us to meet the needs of our customers in China. In the future, a Shell Lubricant Technical Center will be established in Shanghai. In addition, new energy vehicles such as hydrogen hybrids, fuel cells, solar cells, and electric vehicles are a new area that is rapidly developing and exciting. Shell Lubricants will continue to work closely with leading automakers and auto parts manufacturers. Europe, the United States, or China will develop new technologies for the "green" future.

At present, the competition in the entire automobile market has become increasingly fierce. In order to increase market share and increase research and development capabilities, it has become a competitive advantage for various manufacturers to compete in the international and domestic markets. Independent research and development will help lead the market in technology and product differentiation. Following the engine technology, gearbox technology will become a key point in the development of the automotive sector. At the same time, new energy technologies have brought more challenges and unknowns to the gearbox technology. Shell will continue to work on the research and development of related lubricants technologies to help improve production efficiency, reduce lubrication-related costs and achieve sustainable development.

The role of lubricating oil is extremely important for gearboxes that are an important part of automotive powertrains. For both traditional MT/AMT, AT and new technology CVT, DCT, and Shell have corresponding transmission lubricant solutions. Transmission lubricants that have undergone stringent global bench tests and long-cycle road tests have been certified and used by most major OEMs.

In recent years, reducing CO2 emissions and improving fuel economy have been the main goals of transmission development. The development of various new transmission technologies poses very stringent challenges to lubricants. For example, various new friction materials for DCT and AT require that the cooperation of oil and friction materials can provide more efficient transmission and smoothness. Shifting and stable friction characteristics; AT requires lubricants to have lower viscosity (lower viscosity, less energy loss), effective lubrication of gears with a wider range of speeds, and leading transmission manufacturers require Provide life-long maintenance-free; DCT technology requires a lubricant to meet the needs of manual gearbox and automatic transmission. In addition, in Europe, the United States, Japan, and other Asian markets, transmission lubricants are subject to traditional regulations, such as Dexron, Mercon, and the new OEM specifications, how to develop a single oil product to meet as many technical specifications as possible and OEM requirements simplify the selection, reduce transmission oil inventory, reduce risks, and pose very difficult challenges to oil suppliers.

Ms. Tong is primarily responsible for Shell China automotive OEM and automotive component technology project support, and has a very rich technical background and experience in lubricants. She spoke at the meeting: In terms of environmental protection and fuel economy, Shell was proposed as early as in 2002. The concept of "Driveline Lubricant": With the use of Shell's engine oil technology, the new Shell Spirax range of transmission oils delivers more efficient transmission efficiency and fuel economy.

Shell has closely cooperated with the world's leading manufacturers of transmissions and transmission components in the automotive components industry, and has cooperated with many automotive OEMs to develop experience and provide the most suitable lubrication technology solutions. At the same time, Shell China is also actively and leading domestically. Manufacturer cooperation. Shell also has a very strong global R & D capabilities, with R & D centers in Germany, the United Kingdom, the United States and Japan. In order to better support the development of China's business, in August 2011, Shell's first lubricant service center in China was also operational in Zhuhai City, Guangdong Province. Chinese customers will then have the opportunity to experience Shell's lubricant technology capabilities. The center is part of Shell's downstream growth strategy, enabling us to meet the needs of our customers in China. In the future, a Shell Lubricant Technical Center will be established in Shanghai. In addition, new energy vehicles such as hydrogen hybrids, fuel cells, solar cells, and electric vehicles are a new area that is rapidly developing and exciting. Shell Lubricants will continue to work closely with leading automakers and auto parts manufacturers. Europe, the United States, or China will develop new technologies for the "green" future.

At present, the competition in the entire automobile market has become increasingly fierce. In order to increase market share and increase research and development capabilities, it has become a competitive advantage for various manufacturers to compete in the international and domestic markets. Independent research and development will help lead the market in technology and product differentiation. Following the engine technology, gearbox technology will become a key point in the development of the automotive sector. At the same time, new energy technologies have brought more challenges and unknowns to the gearbox technology. Shell will continue to work on the research and development of related lubricants technologies to help improve production efficiency, reduce lubrication-related costs and achieve sustainable development.

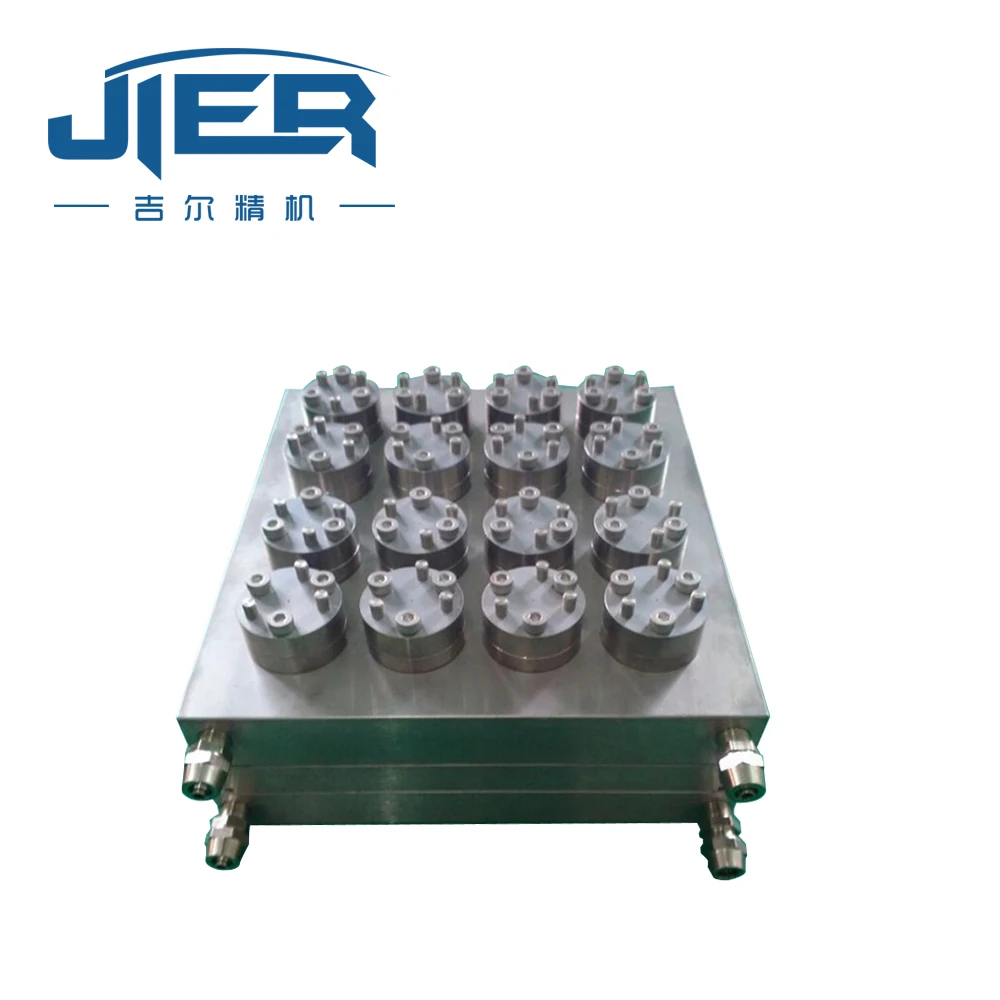

Spinneret for Spinning Hollow fiber Membrane Production Line

1. Grade: SUS431/SUS630

2. Size: Customized

2. Size: Customized

|

Product Name

|

Pet Filament Spinneret Mold Spinning Machine Parts

|

|||

|

Material

|

Stainless Steel

|

|||

|

Grade

|

SUS630/SUS431/SUS316

|

|||

|

Smoothness of Surface

|

Mirror

|

|||

|

Brand

|

JIER

|

|||

|

Ude

|

Extrusion Machine

|

|||

Why Choose Us

Changzhou JIER precision machinery manufacturing Co., Ltd is specializing in the production of various kinds of spray wire plate.We have introduced comprehensive domestic and foreign advanced spray wire plate. For years, through the production process ,technology process and high precision machining testing equipment continuously and automatically innovation and training, together with all staff meticulous work attitude, our spinneret manufacturing level completely meet your requirements of stringent quality of products .

Packing & Delivery

Packing Details : Packing, cardboard box or wooden case

Delivery Details : 30 working days

Delivery Details : 30 working days

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory. And we can supply spinning packs according to your requirements.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for extra charge and do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, balance after the goods have been manufactured. We will arrange the shipment after your payment.

If you have another question, please feel free to contact us.

If you have another question, please feel free to contact us.

Hollow Fiber Nozzle,Corrosion Resistant Hollow Fiber Nozzle,Spinneret For Hollow Fibe,Hollow Fiber Membrane Mold

Changzhou Jier Precision Machinery Manufacturing Co., Ltd. , https://www.jier-spinneret.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)